Εργαστήριο Ανάπτυξης Ολοκληρωμένων Συστημάτων Διεργασιών

Το Εργαστήριο Ανάπτυξης Ολοκληρωμένων Συστημάτων Διεργασιών είναι ένα βασικό εργαστήριο του Ινστιτούτου Τεχνικής Χημικών Διεργασιών, το οποίο βρίσκεται στη Θεσσαλονίκη, στην Ελλάδα.

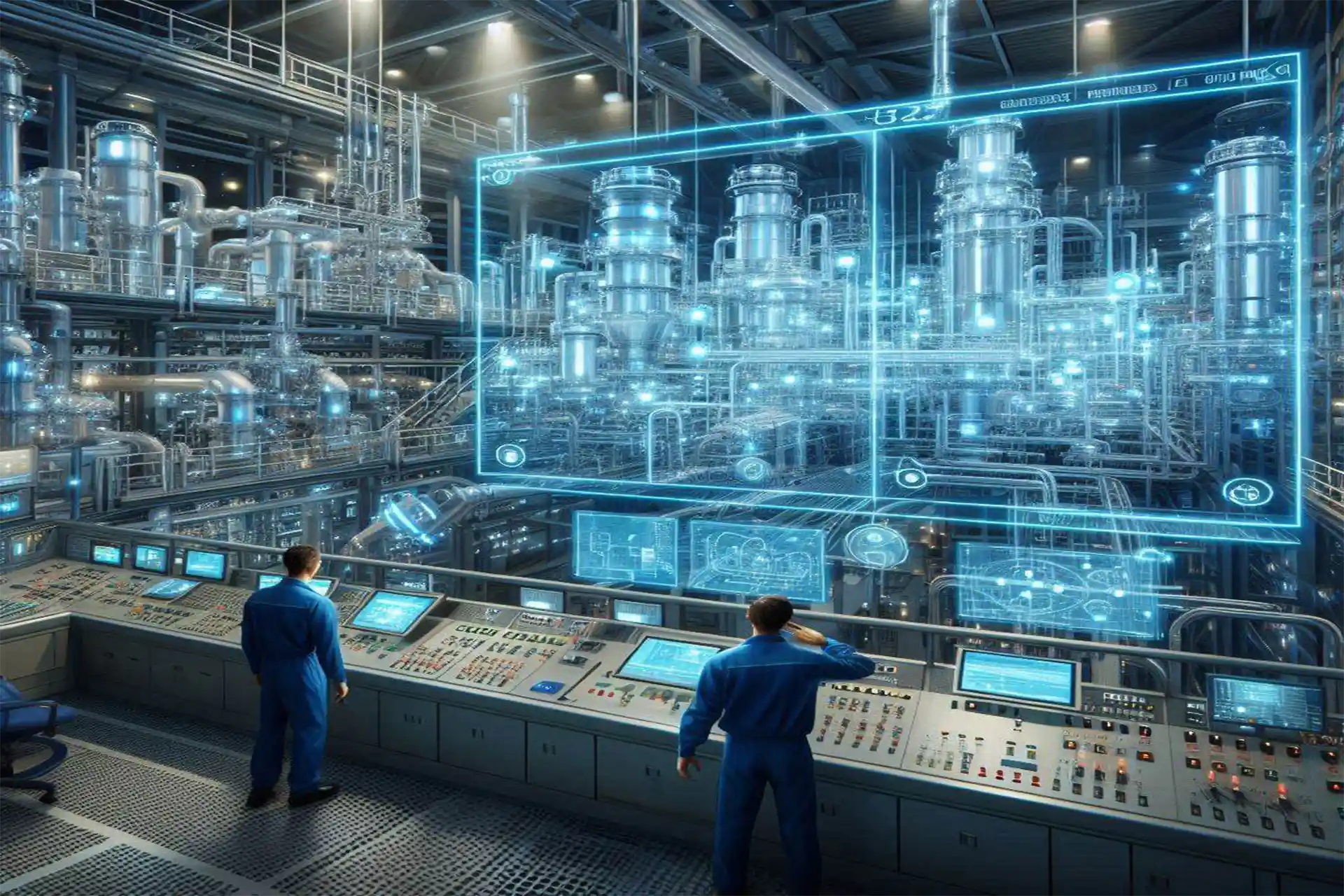

Το εργαστήριο απαρτίζεται από προσωπικό που αποτελείται από ερευνητές, αποφοίτους ανατάτων σχολών, μηχανικούς ελέγχου, τεχνικούς και συνεργαζόμενα μέλη ΔΕΠ. Η υποδομή του εργαστηρίου αποτελείται από πιλοτικές μονάδες (methanol, syngas, hydroprocessing, PEM) , ένα μηχανουργίο 230μ2 ,ένα δωμάτιο βαθμολόγησης και έναν κεντρικό χώρο ελέγχου όλων των εξυπηρετητών.

Επίσης το εργαστήριό μας έχει πάρει μέρος σε πολυάριθμες ανταγωνιστικές Ευρωπαϊκές και Εθνικές έρευνες έργων και έχει αναπτύξει μοναδικές υποδομές, σε Ευρωπαϊκό επίπεδο, και τεχνολογία στα παρακάτω:

- Σχεδιασμό και κατασκευή πολύπλοκων συστημάτων διεργασιών.

- Σχεδιασμό, έλεγχο και βελτιστοποίηση των συστημάτων και των διεργασιών.

- Ανάπτυξη συστημάτων ηλεκτροχημικών διεργασιών.

- Ανάπτυξη θερμοχημικών και καταλυτικών διεργασιών για ενέργεια, καύσιμα και χημικά προϊόντα.

- BTL διεργασίες.

- Παραγωγή υδρογόνου από RES

Στόχοι

Κύριοι στόχοι εργαστηρίου

Αποστολή

Αποστολή Εργαστηρίου

Το Εργαστήριο Ανάπτυξης Ολοκληρωμένων Συστημάτων Διεργασιών (ΕΑΝΟΣΥΣ) επικεντρώνεται στην ανάπτυξη υπολογιστικών εργαλείων για τη βελτιστοποίηση και τον σχεδιασμό διεργασιών και υλικών.

Σχεδιασμός και κατασκευή πολύπλοκων συστημάτων διεργασιών

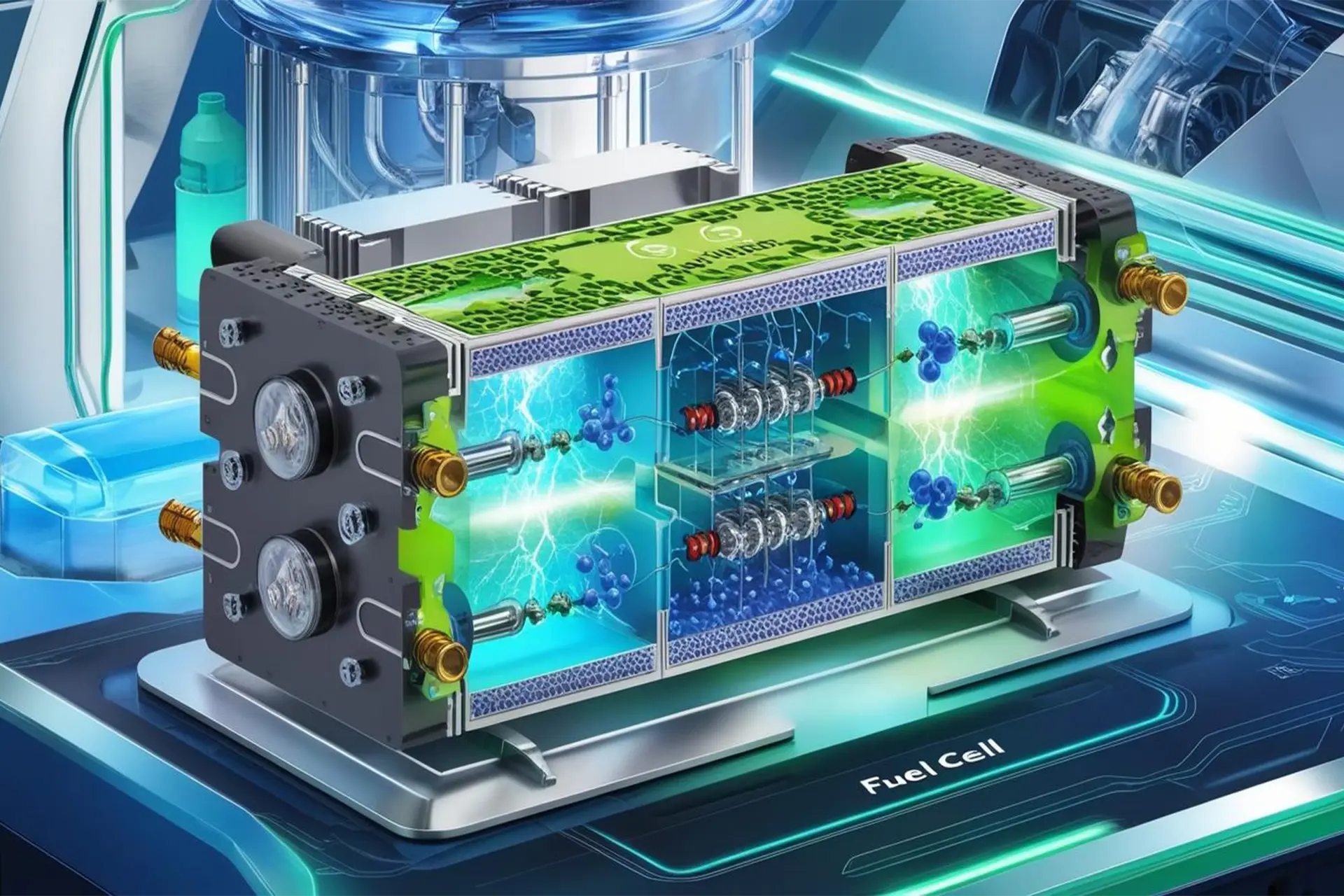

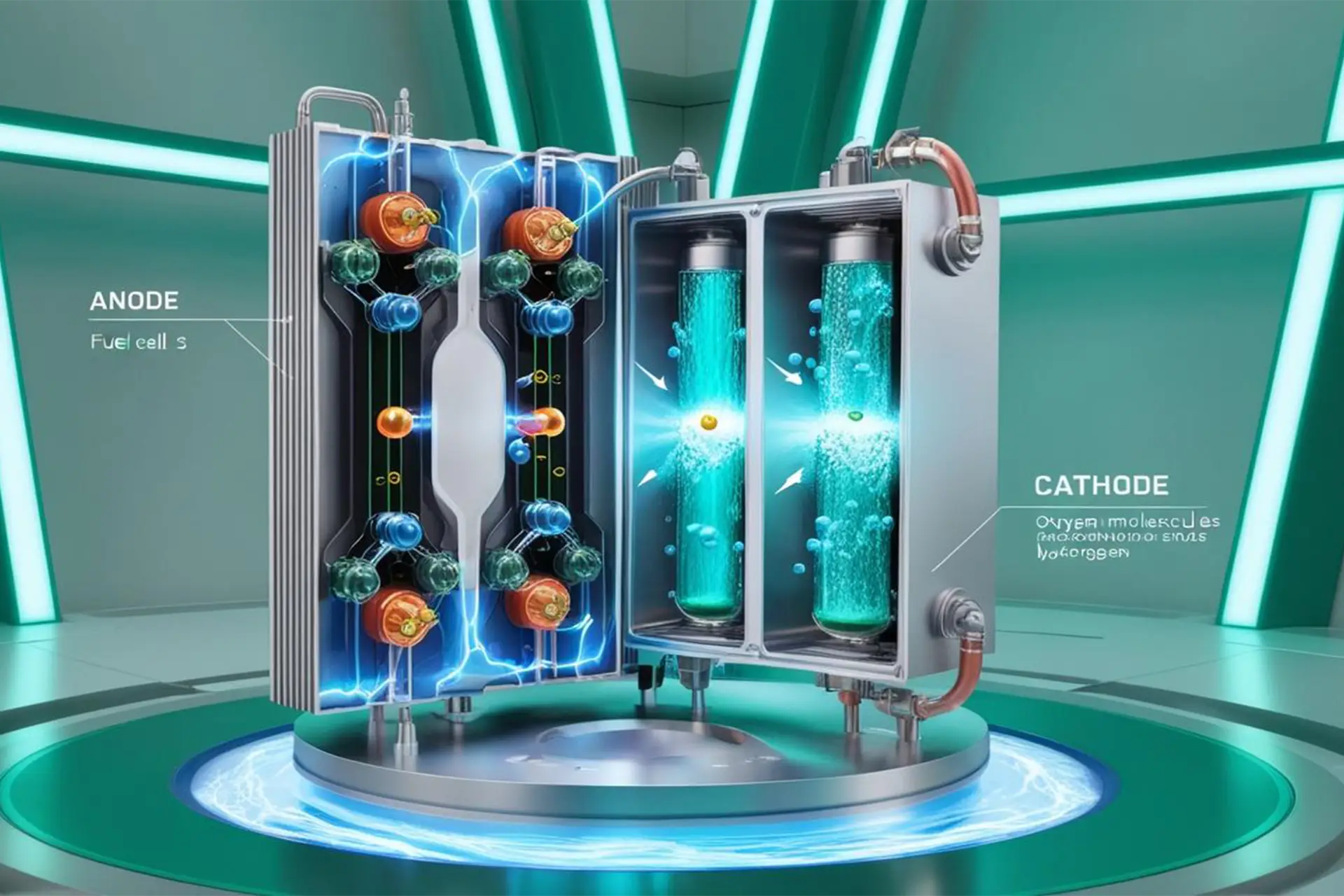

Kυψέλες καυσίμου

Η παραγωγή ενέργειας και καυσίμων από ανανεώσιμες πηγές ενέργειας

Νέα συστήματα παραγωγής ηλεκτρικής ενέργεια

Οι Επιστημονικοί & Τεχνολογικοί στόχοι αφορούν την ανάπτυξη καινοτόμων λύσεων και τη βελτίωση της επιστημονικής και τεχνολογικής έρευνας για την επίτευξη προηγμένων επιδόσεων και βιώσιμης ανάπτυξης.

Στόχοι

Επιστημονικοί & Τεχνολογικοί

Ανάπτυξη μοντέλων

Προηγμένος έλεγχος αυτοματισμού

Εξερεύνηση πρακτικών εφαρμογών του φαινομένου της ηλεκτροχημικής ενίσχυσης

Ανάπτυξη του καταλύτη ηλεκτροδίων για χρήση ως άνοδος σε κυψέλες καυσίμου PEM & SOFC

Βελτιστοποίηση των πολύπλοκων συστημάτων των διαδικασιών με έμφαση στις τεχνολογίες για την αξιοποίηση των εναλλακτικών πηγών ενέργειας και των ανανεώσιμων πηγών

Δραστηριότητες

Δραστηριότητες του εργαστηρίου

Επικοινωνήστε μαζί μας

Για συνεργασίες ή απορίες, μη διστάσετε να επικοινωνήστε μαζί μας